Refractron’s porous alumina tubes are an integral component for the root-zone management system for next generation space crop production. Refractron optimizes the tubes by improving strength and adjusting the pore size to deliver robust tubes that can be used for several generations and give researchers precise control to study drought and micro-gravity conditions.

Partnering with Utah State University to Develop Crop Water Content & Nutrition Control Solutions

The Crop Physiology Laboratory at Utah State University was funded by NASA to develop sustainable strategies for its next-generation, multi-generational plant production system, Ohalo III.

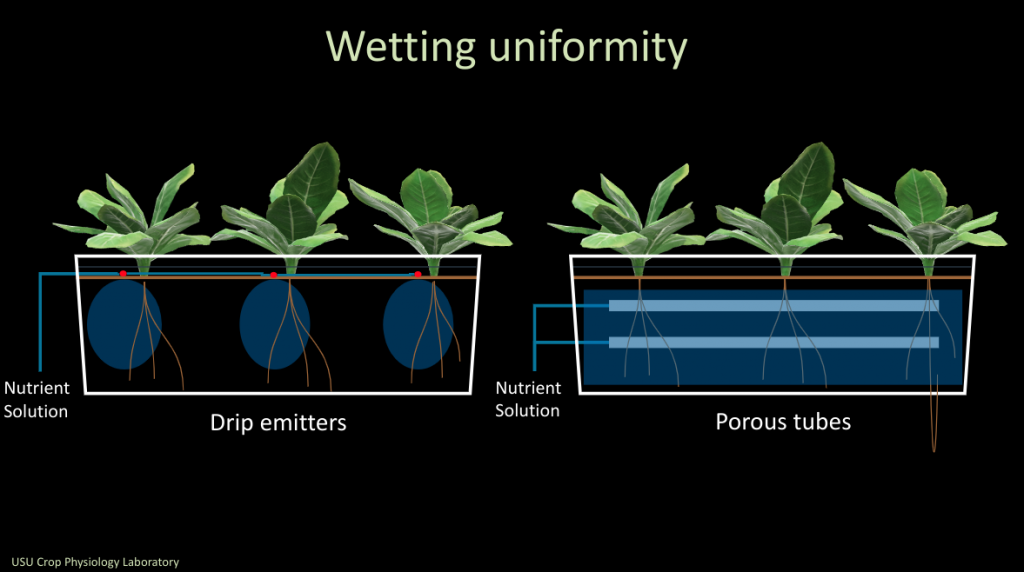

One of the key components of a successful plant production system is controlling the water content and nutrition in the root zone which is particularly challenging in the absence of gravity. Without gravity to move nutrients through the growth media profile, conventional irrigation methods fail to evenly distribute water and nutrients in the root-zone. This can result in non-uniform wetting, where part of the root-zone experiences drought stress while another part may be flooded. The resulting dehydration or hypoxic conditions results in poor root development and reduced growth.

Utilizing custom designed Refractron ceramic tubes to interface a hydroponic nutrient supply with the porous rooting media allows for fine control and uniform distribution of nutrients and water, minimizing zones of high saturation. Properly designed rooting media further aids in distributing irrigation once it enters the root-zone through the porous tubes. Precision electromagnetic sensors are used for careful monitoring of root-zone nutrition and hydration and exact quantities of fertilizer and water can be applied based on real-time plant demands. This not only prevents over or under-watering but also helps minimize water and fertilizer waste.

Ceramic Products Are The Ideal Aid for Space Plant Growth

Sustainable plant-based bioregenerative life support systems are necessary to support long-duration space missions. These ecosystems provide a source of food, remove carbon dioxide from the atmosphere, and provide potable water through transpiration. Live plants also provide a distinct psychological benefit to humans on extended missions.

Ceramic materials are better suited to long-term moisture and salt exposure compared to stainless steel components and can be left embedded in the plant growth system across multiple, continuous cropping cycles. This high degree of reusability meets the sustainability requirements for NASA’s next-generation plant production system for space and further solidifies Refractron porous ceramic tubes as the clear choice for this critical system under development at Utah State University.

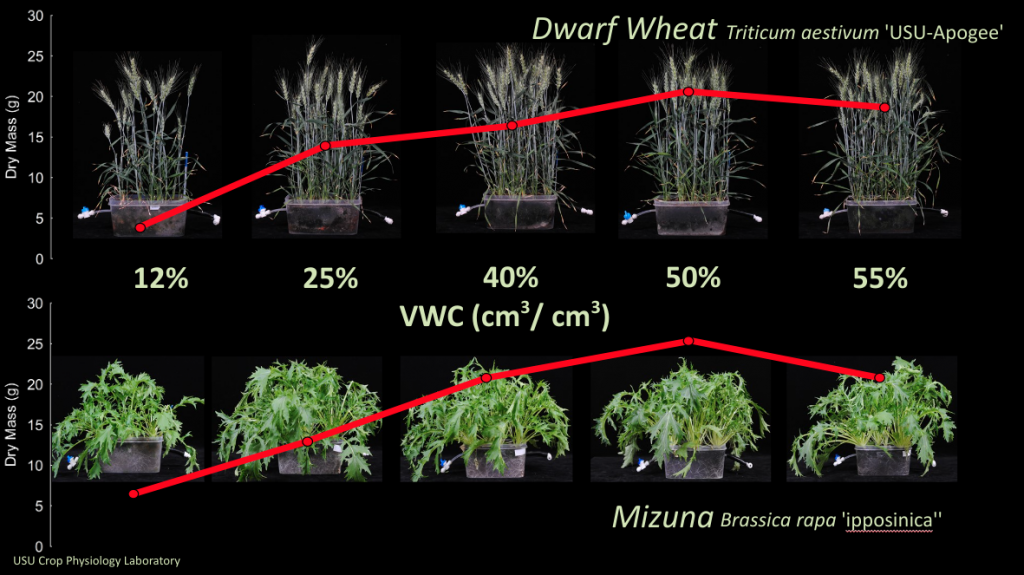

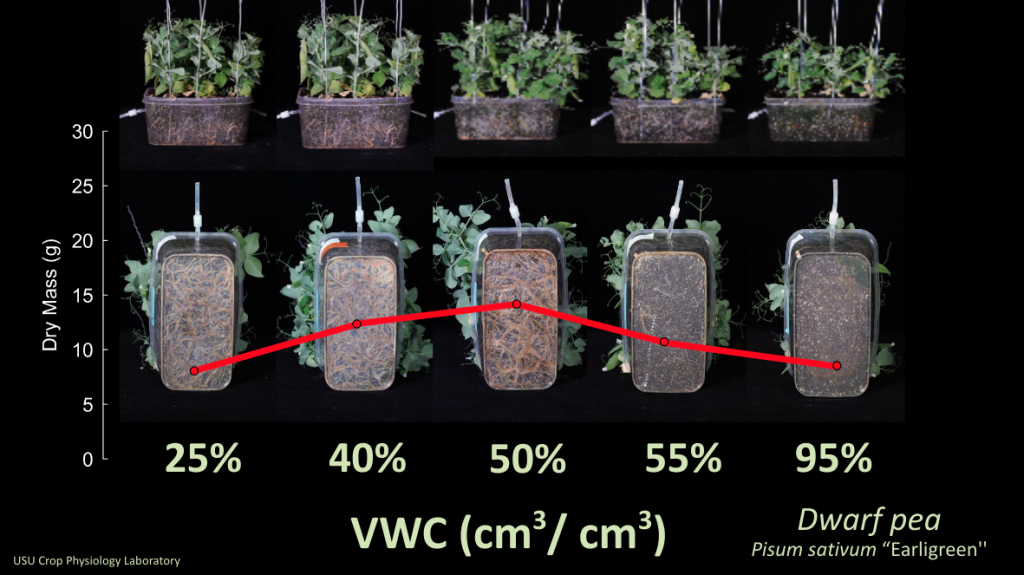

The provided slides from below from Utah State University’s College of Agriculture and Applied Sciences’ Crop Physiology Laboratory show the impact of a ceramic tube integration into a crop-growing “root zone” module:

Contributing Author: Tyler Roberts

Tyler Roberts is a Chemical Engineer at Refractron Technologies. Contact Tyler at +1 (315) 879-0811 or troberts@refractron.com for a free assessment to see if we can help you with parts that will extend maintenance cycles, improve product quality and process reliability and reduce your operational costs.